Alternative protein is a general phrase that refers to foods, ingredients, or beverages that have protein derived from non-animal sources such as lab-grown meat, plant-based meat, single-cell proteins from yeast or algae, and edible insects. Cultivated meat is a category of alternative protein, made from real animal cells without the cruelty of raising animals in confinement. Cells taken in a small biopsy from a living animal are cultivated in a growth medium that provides nutrients to the cells as they proliferate. The benefit is that the resulting product tastes like animal meat because it’s grown directly from animal cells.

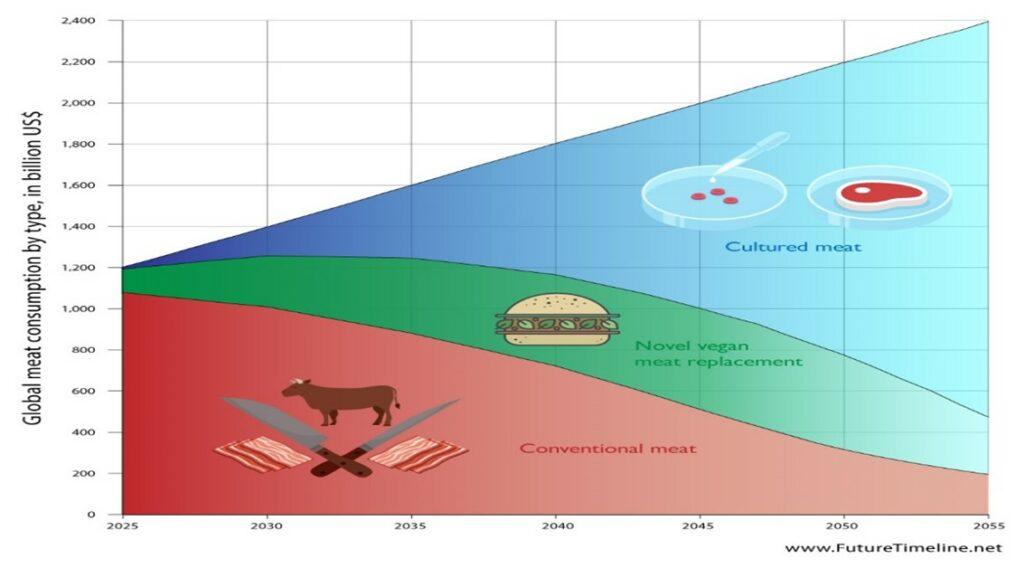

In a recently published article of RethinkX, it is reported that this increasing technique will lead to a profound disruption on industrial animal farming. By 2030, demand for cow products will have fallen by 70%. By 2035, demand for cow products will have shrunk by 80% to 90%. Other livestock markets such as chicken, pig, and fish will follow a similar trajectory. The current industrialized, animal-agriculture system will be replaced with a Food-as-Software model, where foods are engineered by scientists at a molecular level and uploaded to databases that can be accessed by food designers anywhere in the world. The cost of modern food products will be half that of animal products and they will be superior in every functional attribute – more nutritious, tastier, and more convenient with much greater variety.

New alternative sources of protein are emerging as they are crucial to nourishing our growing population while mitigating the effects of the climate crisis.

Some of the recent technological developments in the area of alternattive protein sources are:

- ‘Precision fermentation’, where scientists give the microflora the precise DNA sequence that provides a blueprint for making cow whey and casein proteins. The microflora is put into a tank filled with broth, which is made of water, nutrients and sugar. Because the microflora have the blueprints for making the two proteins, when they ferment the broth, they can make pure animal protein. From there, the protein is separated from the microflora, filtered, purified and finally dried. The company says what you get from all of this is a pure protein powder that can be used to make milk, cheese, yogurt, cream cheese and even ice cream — all of which are identical to the original dairy products.

- A Singapore-based biotech company also aims to produce cell-based milk, but human milk as well. Firstly, they obtaining stem cells from sources such as milk. They are then transferred into an environment where they convert into mammary gland cells. The mammary gland cells interact with a special formula which causes the cells to lactate. The end product - milk is obtained through a filtration process. Another company also targeted to develop alternative human breast milk.

- Other companies also reached success with protein prodution by microbes, minced meat-like protein is produced by a specific bacteria strain.

- Besides microbial cultivation, plant-based protein products, such as Plant-based egg, made of mung beans and turmeric is selled by a company, however, a product recall have raised the awareness of potential allergens and fraud as whole-egg and milk products were found in some types of their products.

- With a hybrid method, combining both animal cells and plant-based proteins and fats, lab-grown bacon and pork belly has also been revealed.

- Insect-based protein sources are also on the table. A literature study by Schothorst Feed Research shows that housefly larvae are a viable protein source in sustainable layer nutrition which can fully replace soya. If production of larvae can be up-scaled and implemented on layer farms, larvae will be price-competitive with soybean meal. Currently, EU legislation limits the use of larvae for poultry, but this is likely to change in the future.

- Mushrooms as alternative protein sources: Mushrooms, including edible mushrooms and foods fermented by mushrooms, have the potential to use inexpensive feedstocks to produce biomass and protein. Harnessing the potential of the mushroom mycelium to produce high quality plant protein is perfectly in line with both consumer expectations and the EU's commitment to sustainability and food security (see for example this product).

Updates

Favourable decision in the USA

First lab-grown meat is considered safe for consumption by United States FDA (Food and Drug Administration) in 2022 November. The product is a cultivated chicken made by Upside Foods. The FDA "evaluated the information submitted to the agency and has no further questions at this time about the firm's safety conclusion," the agency stated. However, it cannot be sold in the market until the approval of U.S. Department of Agriculture Food Safety and Inspection Service.

First global consultation on the safety of cell-based foods

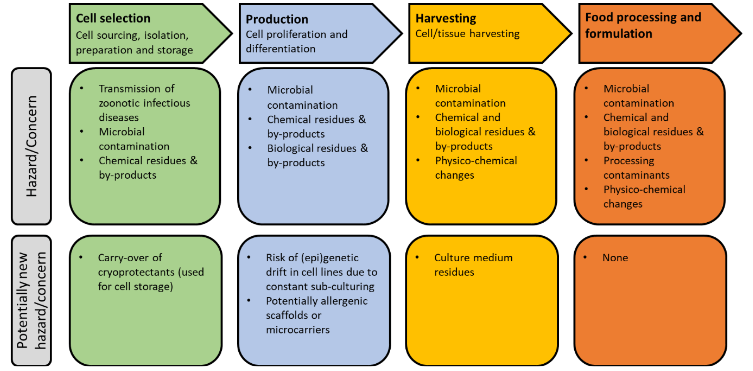

In November 2022, an international group of experts investigated the potential food safety problems associated with cell-based foods in a meeting organized by the Food and Agriculture Organization of the United Nations (FAO), in collaboration with the World Health Organization (WHO). In preparation for the expert consultation, three technical background documents were prepared: 1) Terminologies; 2) Generic production process; and 3) Regulatory frameworks.

Cell-based food production involves culturing cells isolated from animals followed by processing to produce food products that are comparable to the corresponding animal versions, such as meat, poultry or aquatic animal products.

The experts found that with cell-based food, we run the same risks as with conventionally produced food: the occurrence of microbiological contamination, chemical residues or by-products during production or processing. The experts concluded, however, that microbial contamination during culture would typically be expected to inhibit cell growth. If the cells have grown and reached product expectations for harvest, that means that such contamination did not occur during the production process but still could post-harvest, as in any other food products.

Risk mitigation tools available for the management of existing hazards, such as good hygienic practices and Hazard Identification and Critical Control Points (HACCP), are applicable to this production methods as they are in conventional food production, the experts said.

The technical panel highlighted that food safety assurance plans would also need to pay a close attention to the use of materials, inputs, ingredients and equipment that can be specific to cell-based food production. However, while such applications can be new, experts concluded that existing preventative measures and safety assurance tools will be applicable to control such hazards.

The results of the expert consultation will be made available in a publication to be launched in early 2023.

Mushrooms as alternative protein sources

MycoTechnology has received Novel Food status from the European Commission for two of its plant protein ingredients. The European Food Safety Authority has deemed the fermented pea and rice protein blend safe for use in food and beverages. MycoTechnology's proprietary process deodorizes and de-flavors the protein to offer a neutral solution with high functionality. The available formats of FermentIQ™ are designed to improve solubility and mouthfeel in protein beverages, deliver nutrition, taste, and mouthfeel profiles suitable for dairy alternatives, and offer spring and juicy textures in meat analogues. The ingredients both have a Protein Digestibility Corrected Amino Acid Score of 1 for individuals aged three and older. The company is looking to accelerate its expansion into Europe following the authorization. MycoTechnology's CEO believes that harnessing the power of mushroom mycelia to produce high-quality plant protein is perfectly aligned with both consumer expectations and the EU's commitment to sustainability and food security. The company is already in conversations with leading food industry players in Europe to formulate and commercialize products containing FermentIQ™ plant protein.

A recent article discusses the growing global demand for protein sources and the need for innovative and sustainable alternatives. The authors highlight the potential use of fungi, including edible mushrooms and single cell proteins (SCP), as alternative sources of protein for human consumption and animal feed. Fungi, with their ability to consume inexpensive waste products as sources of carbon and energy, offer a unique solution to the protein shortage problem. The article also discusses the safety of consuming fungal fermented foods and SCP. The authors emphasize the significant role of academia, United Nations Organizations, industries, political makers, and others in exploring and promoting the use of fungi as an alternative protein source.